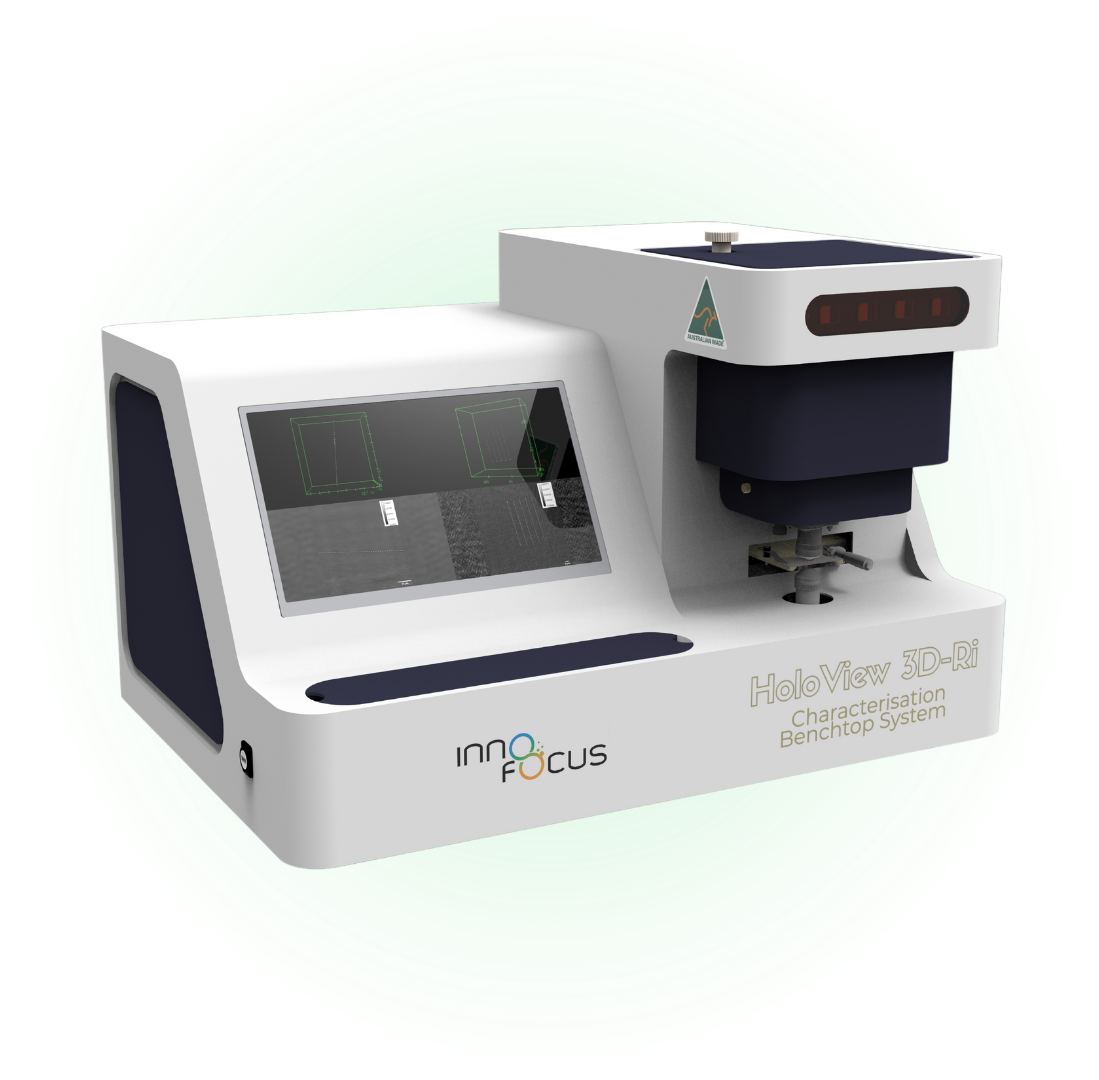

HoloView Benchtop 3DRI

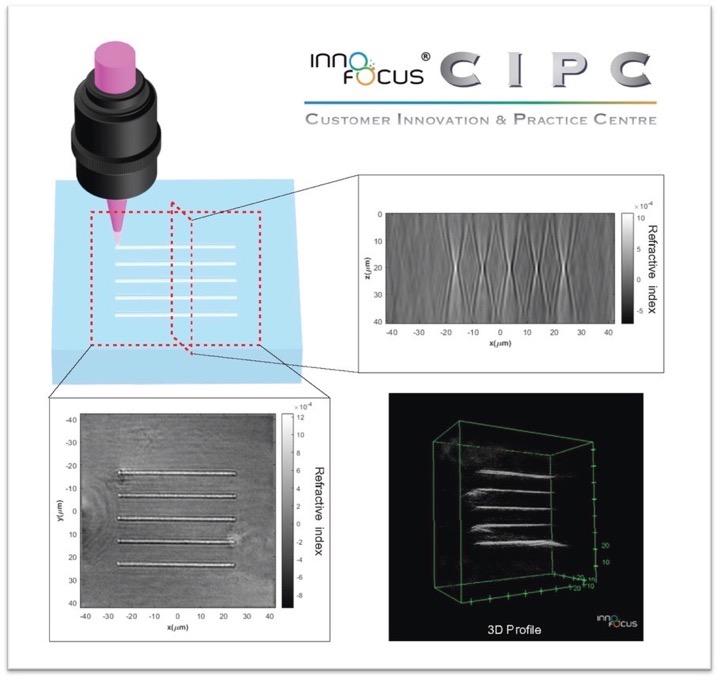

World-only Benchtop 3D Refractive Index Characterization System provides high index accuracy (10-4), simple operation, fast characterization speed at about 0.5 fps, allowing quantitative measurement and rapid optimization of photonic nanomanufacturing parameters and processes.

- In-situ characterization of refractive index of optimal design and fabrication parameters

- Fast Characterization Speed (0.5 Fps)

- Characterize available for various devices (eg. FIFO, WDM, FBGs)

- Characterize available for a wide range of materials including polymers, glasses (incl. chalcogenide glass), crystals (eg. LiNbO3), sapphires, transparent ceramics, quartzes, fibers and etc.

- Convenient one-click operation design, with minimal time consumption and manual operation interference, ensuring high efficiency in processing

- Suitable for a wide range of applications to test surface and internal refractive index distributions under harsh environment conditions

- Provide a quantitative reference index system for 3D refractive index measurements, which is continuously being enriched

- Obtain unique data for 3D refractive index distribution to assist cutting-edge scientific research

Industry Challenge

The rapid advancement of information technologies in the 21st century has indicated the approaching post-Moore’s law era. Moore’s law, which dictates the doubling of transistors on microchips every two years, has driven traditional computing technology for many years. The demand for higher speed, larger bandwidth, lower energy consumption, and improved security and stability in information technologies continues to grow. However, as we near the physical limits of miniaturisation, new approaches are needed to continue advancing computation.

Integrated Photonic Chips (iPC) have emerged as a promising successor to silicon chips. With the continuous development, iPCs which offer the desired features including high speed and low power consumption, has become the best solution for high-throughput communication technology. However, as 3D photonic chips move towards commercialisation and industrialisation, existing fabrication capabilities face significant challenges concerning precision, reproducibility, and scalability to fulfil the needs for R&D and manufacturing. There is currently no effective measure to accurately characterise the three-dimensional structural changes formed inside an optical crystal by femtosecond laser, as well as the resulting refractive index distribution and morphology. To fabricate 3D optical structures in optical crystals, the difference in refractive index introduced by laser processing is particularly important, which determines the design of the component and its loss.

Therefore, to effectively characterise the fabricated nanostructure/nanopatterns and provide timely feedback to the fabrication process has become one of the key challenges in quality control for processing 3D photonics chips.

HoloView 3DRI, the 3D in-situ refractive index characterisation system designed by Innofocus, has proved to enable characterise the 3D spatial refractive index distribution with our newly-developed optical imaging technology and image reconstruction algorithm. The system can precisely measure the refractive index distribution in material and effectively reconstruct the refractive index distribution, and form image of the 3D structure with an accuracy of 10-4. It is non-destructive and non-invasive, and it allows real-time monitoring the fabrication process, making it valuable for the applications in the disciplines of all-optical communications, sensors, biophotonic and micro/nano optical and photonic devices.

Two-step process for fabrication and surface morphology

Time-consuming

Destructive and Invasive to materials

Affect fabrication results

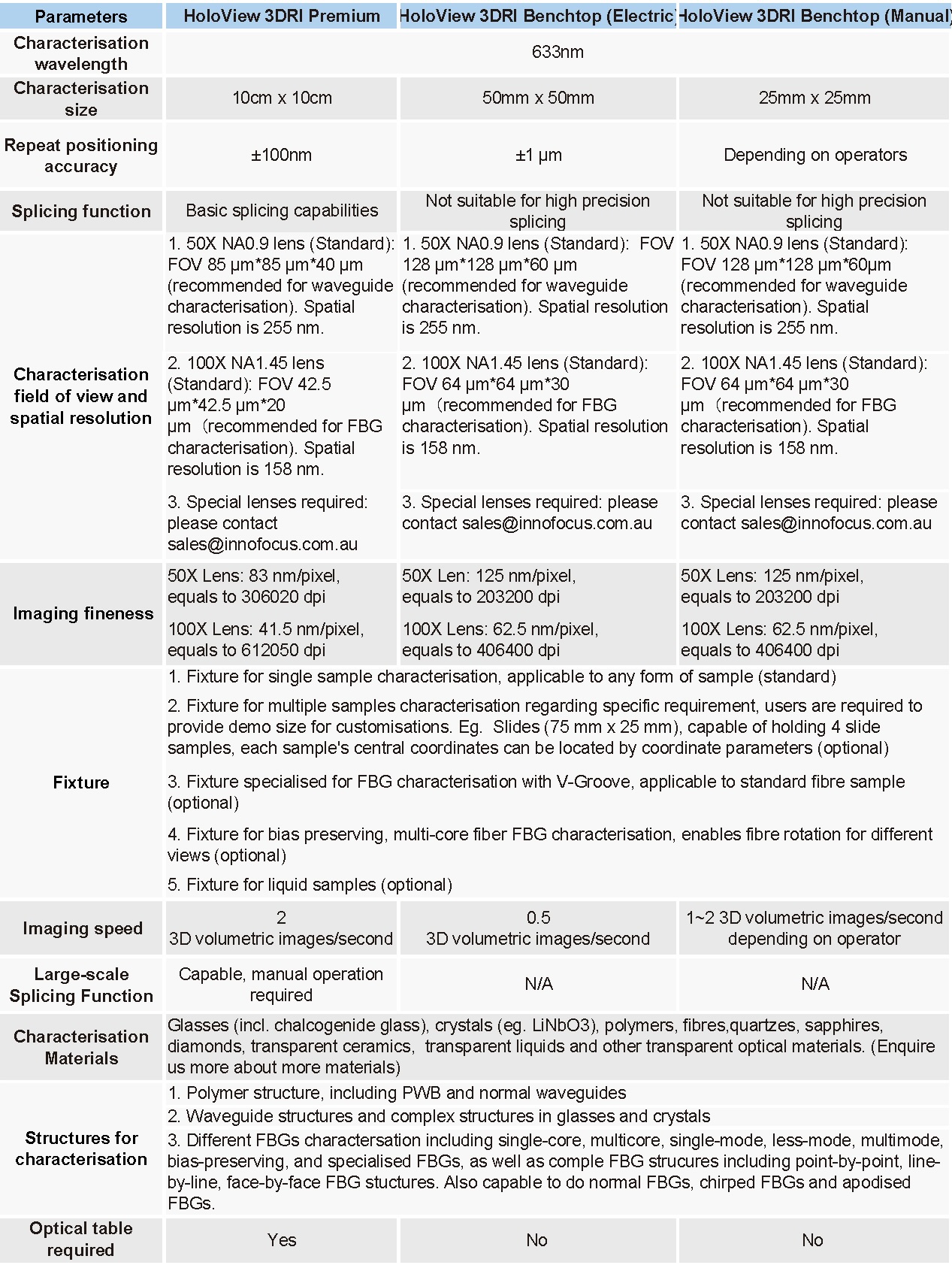

Product Performance

The key properties of an optical component are its refractive index distribution and surface morphology. High-performance optical components can only be fabricated when meeting requirements for both of the properties. Otherwise, distortion in electric field pattern, transmission loss and imperfection will occur, degrading the performance of the components.

Meanwhile, by understanding the refractive index variation and distribution, properties of the optical material and components are quantified, which can be used to indicate whether the material or component is damaged.

For those optical components that are sensitive to variation of refractive index, e.g. optical waveguide and optical fibre gratings, there is no standard quantitative method to characterise their 3D refractive index distribution. This issue has become a bottleneck for accurately designing and fabricating optical components like 3D photonic chips.

To solve, Innofocus has developed world-unique technology of 3D spatial characterisation of refractive index to measure the refractive index difference between the structure designed and the substrate material, with an accuracy of 10-4. The system can not only precisely measure the distribution of refractive index differences, but also reconstruct the 3D surface morphology of the fabricated structure.

The main functions of the Innofocus HoloView 3DRI include:

In-situ inspection of the refractive index difference,

Quantitative measurement of both the surface and internal refractive index distributions of the components,

Imaging functionality which visualises the quantitative measurement of the refractive index distribution.

Applications

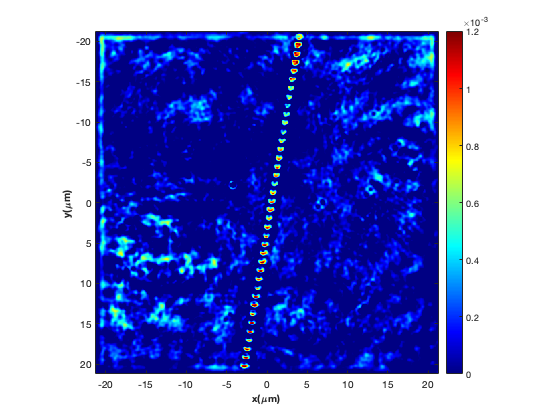

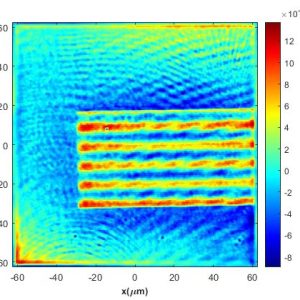

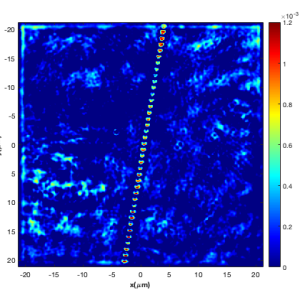

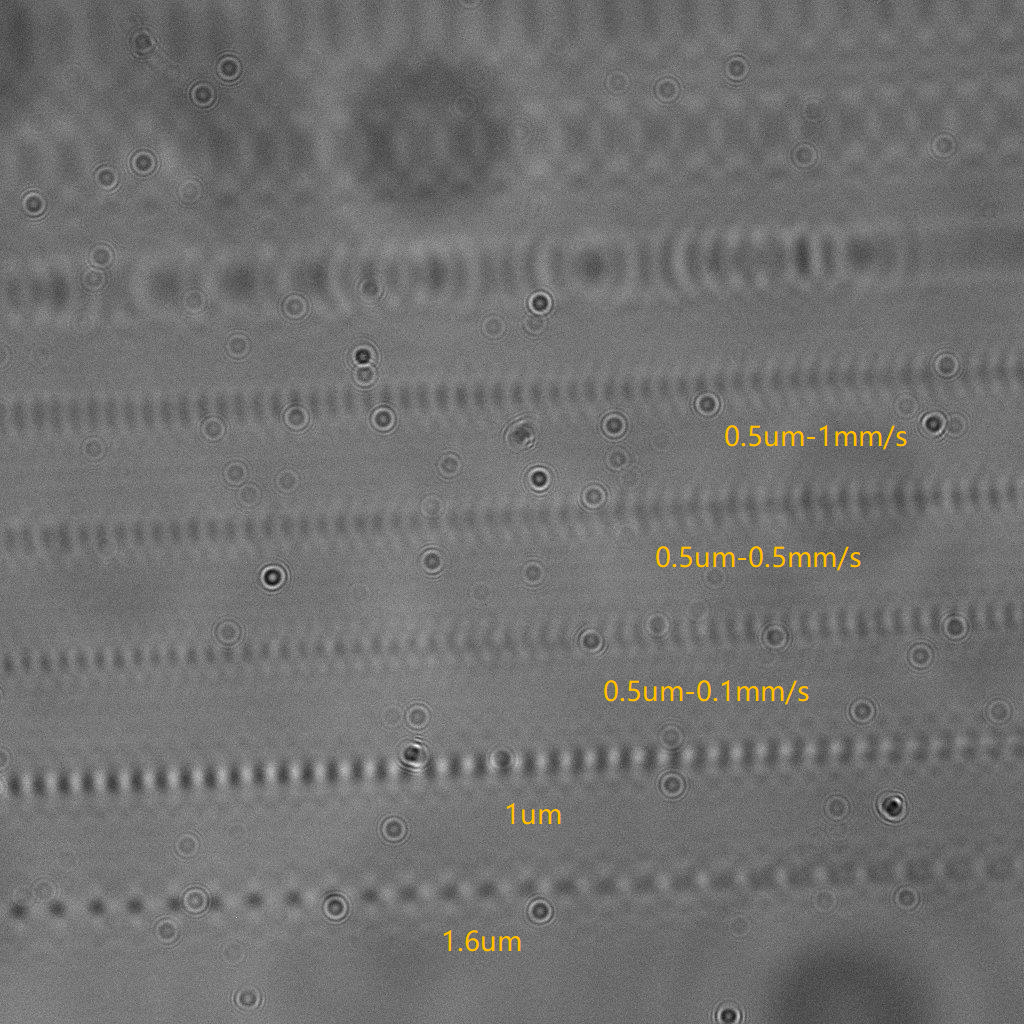

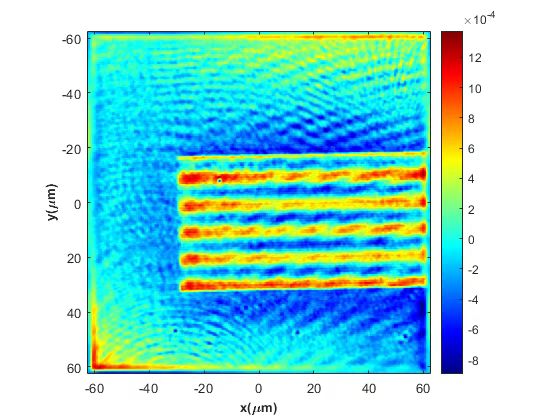

Refractive index characterisation X-Y image