Double Win for InnovationAus 2025 Awards for Excellence : Translation Hero Award & People's Choice Award

World-First nanoFACTORY i-QPC: all-in-one solution for arbitrary 3D nanostructure design and mass production

nanoFACTORY r-FBG: Fully-Automated Roll-to-Roll Fiber Delivery and Collection for Ultrafast FBG Manufacturing

Innofocus Invites Global Customers to Challenge Our FBG Manufacturing Capabilities

HoloView 3DRI Benchtop: World-only Available Commercial Equipment with High-resolution In-situ 3D Refractive Index Distribution Characterizing and Imaging Functionality

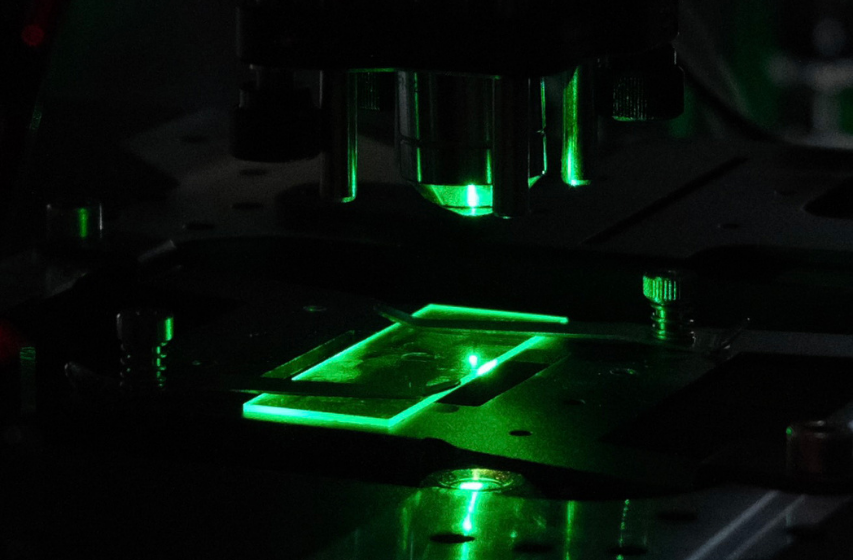

nanoLAB HoloView 3DRI: World-First Intelligent 3D Nanofabrication Equipment with In-situ 3D Refractive Index Imaging Functionality

Why Innofocus?

High Resolution: Sub 100 nm Resolution

High Yield: 400X Faster Speed

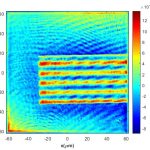

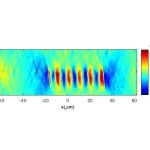

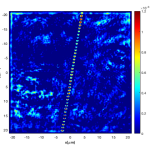

Characterization: In-site 3D Refractive Index Imaging

Multimaterial applicable: From Hardest To Softest

Various Applications: Advanced ICT/Quantum, MedTech

Building the Ecosystem: Open Labs and Platform

Our Featured Products

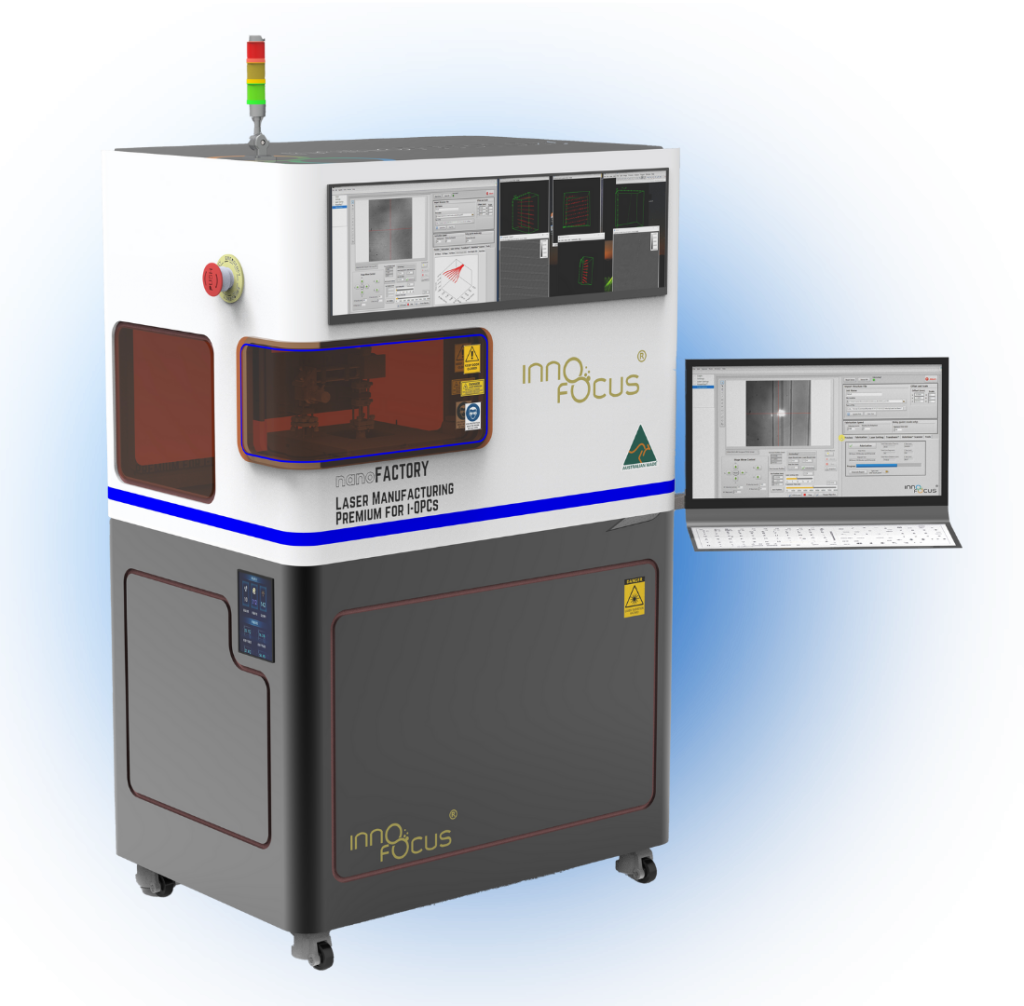

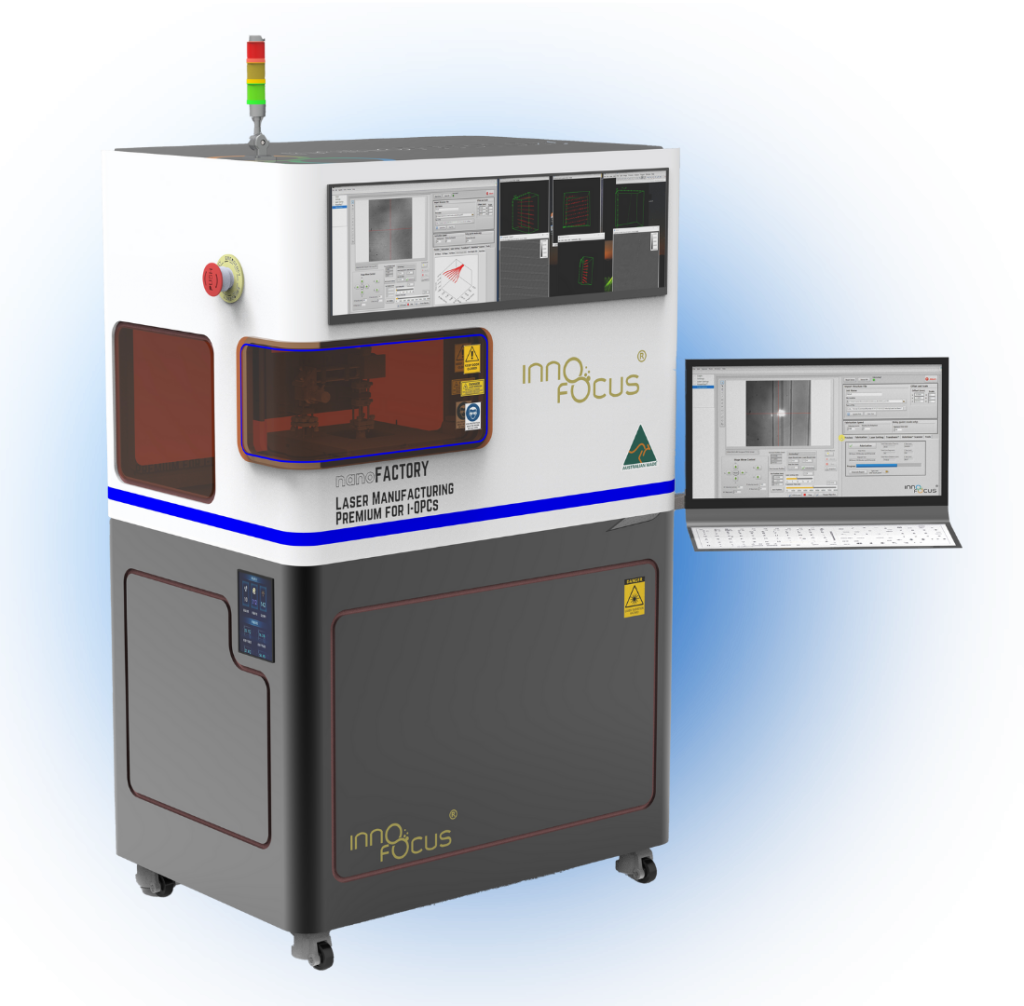

nanoFACTORY i-QPC

A one-stop manufacturing system that meets the needs of industrial-scale nanomanufacturing production lines with high resolution, high efficiency, high accuracy, high device performance and high yield. It can manufacture integrated photonics chips for optical communications, optical sensing, optical computing, and quantum tech.

- Improve exisiting nanoLAB series for the research market.

- Develop nanoFACTORY series for the manufacturing equipment market with high yield, high efficiency, and lower unit cost.

- Specialised for quantum photonic chips fabrication.

nanoFACTORY r-FBG

- Fully automated continuous FBG fabrication up to km length

- High precision fiber delivery and collection system

- AI Vision assisted automated fiber core recognition

- Built-in recipe with standard FBG parameters

- Integrated independent vibration isolation system

- Able to fabricate with multiple fiber types

- Able to fabricate multiple grating structures

- 95% yield of high performance and consistency FBGs

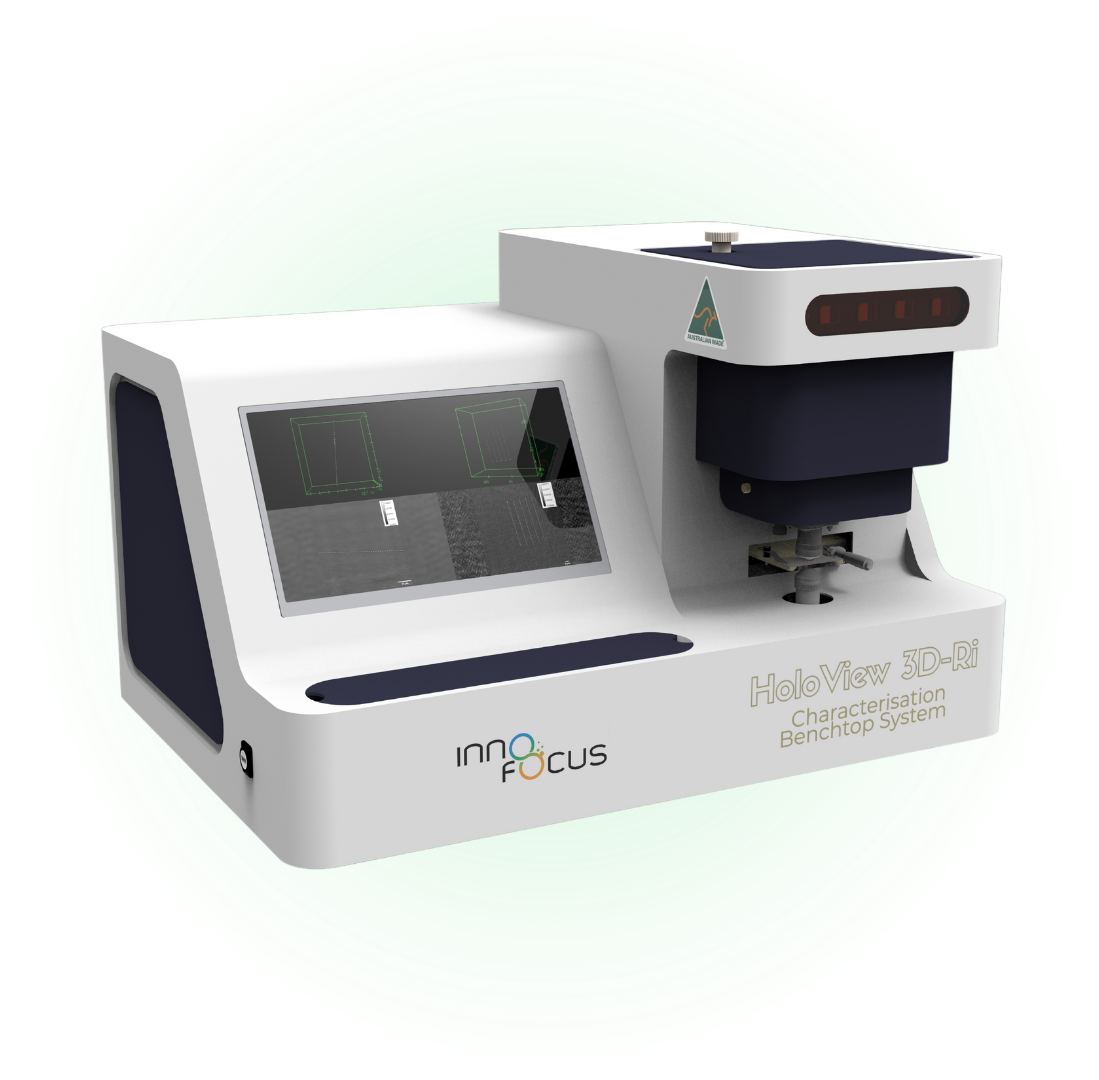

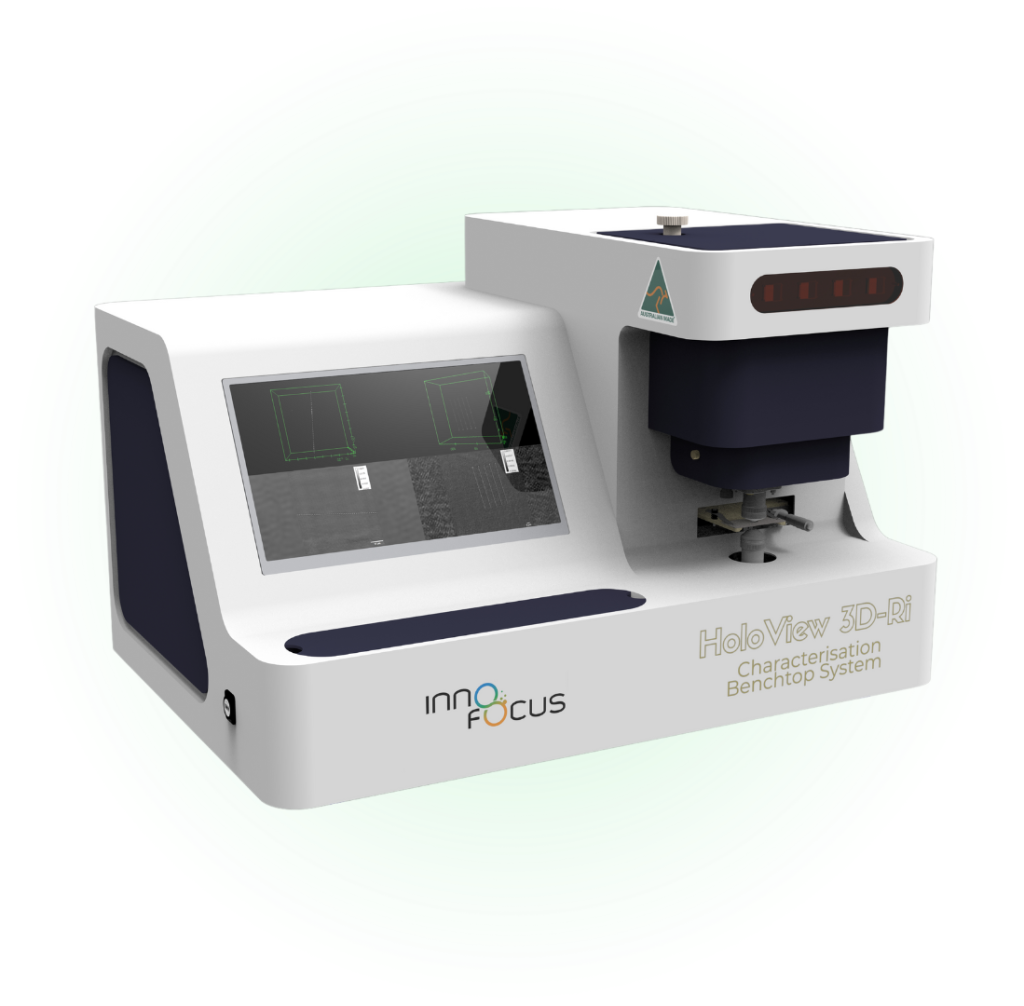

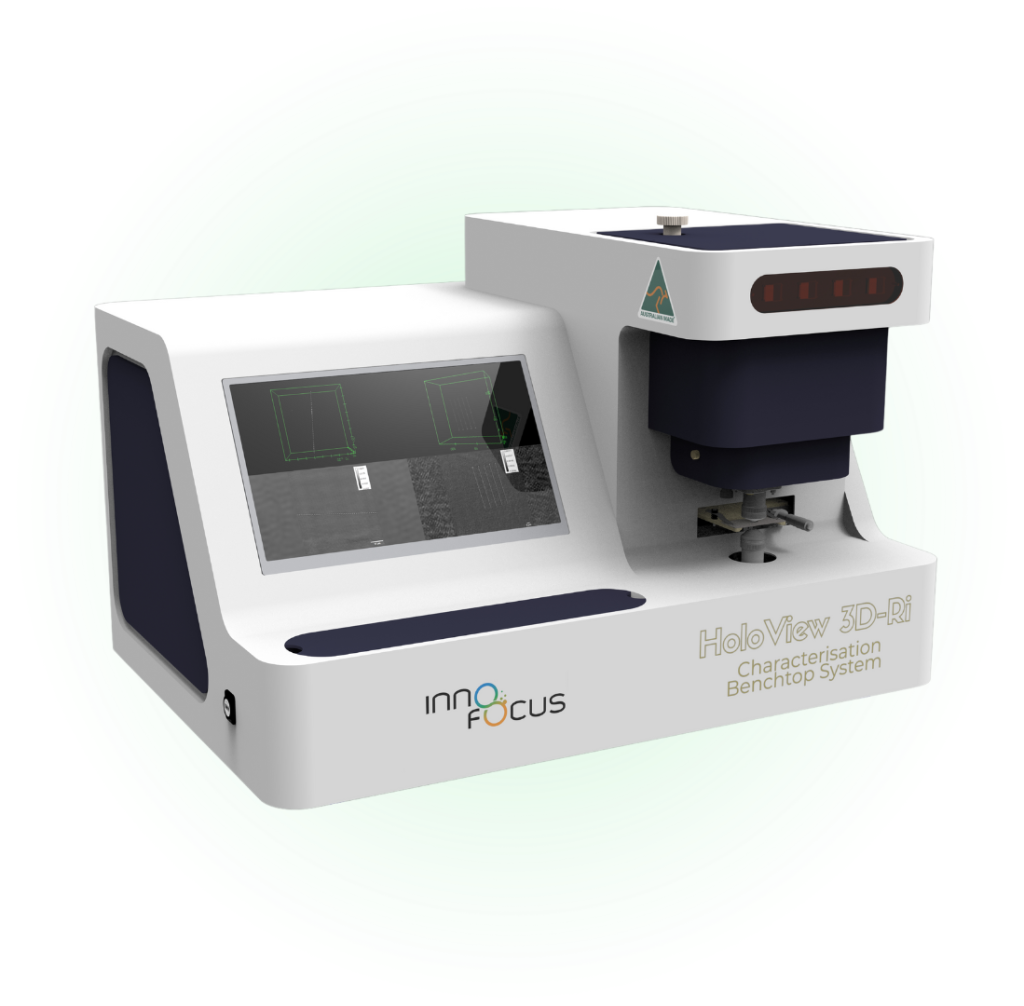

HoloView 3DRI Benchtop

- World-only available commercial equipment with high-resolution in-situ 3D refractive index distribution characterizing and imaging functionality.

- In-situ characterization of refractive index of optimal design and fabrication parameters

- Fast Characterization Speed (0.5 Fps)

- Characterize available for various devices (eg. FIFO, WDM, FBGs)

- Characterize available for a wide range of materials including polymers, glasses (incl. chalcogenide glass), crystals (eg. LiNbO3), sapphires, transparent ceramics, quartzes, fibers and etc.

- Provide a quantitative reference index system for 3D refractive index measurements, which is continuously being enriched

- Suitable for a wide range of applications to test surface and internal refractive index distributions under harsh environment conditions

- Convenient one-click operation design, with minimal time consumption and manual operation interference, ensuring high efficiency in processin

- Obtain unique data for 3D refractive index distribution to assist cutting-edge scientific research

nanoLAB HoloView 3DRI (H3D)

World-first intelligent laser nanofabrication system with our unique in-situ 3D refractive index imaging functionality, meeting the customers’ needs from both academia and industry.

- High degree of automation

- Intelligent advice on parameter configuration

- Scenario-oriented solution package

- SOP-based software module

- Embedded optimized fabrication algorithm package

- Easy to learn and use

- Safe and reliable

- In-situ 3D refractive index characterization functions

UFBGs

Femotosecond laser fabricated FBGs. Standard UFBGs have reflectivities ranging from 30% – 90%, and specialised UFBGs are fully customizable tailored to your needs.

- Highly customizable reflectivity (up to 99.99%, down to <0.001%)

- High consistency (consistency deviation can be controlled within +/- 1 dB)

- Fully customizable in parameters (central wavelength, grating length, etc.)

- High temperature stability (PI coating applicable to temperature up to 800 degrees, AC coating applicable to temperature up to 300 degrees)

- High pressure stability (up to 60 MPa)

Self-cooling Film

The world’s best Self-cooling film that cool down any object without using electricity.

- Unique nanostructures enabled by our world-leading nanomanufacturing capabilities create a brand-new material with superior cooling performance

- Radiative cooling principle

- Proven superior cooling performance

- Ultrathin, easy & flexible for integration enables applications in various industries

- UV comletely blocked

- Cost-effective & mass-production ready

World-first Nano Manufacturing Plant (NMP)

Committed to continuous innovation and open collaboration with customers across industries, Innofocus has established a 1,000 square metres world’s leading Nano Manufacturing Plant (NMP) in Melbourne, with full suite of equipment and instrument, to provide services from PoC, design, simulation, prototyping, manufacturing, testing to integration.

Thanks To Our Collaborators!

From Our LinkedIn Feed

News

Innofocus Food Transportation and Preservation Discussion with Costa

Semiconductor Sector Service Bureau (S3B) Director Dr Nadia Court Visited Innofocus

Innofocus Won InnovationAus 2024 Awards for Excellence in Food & AgriTech for Cooling Film

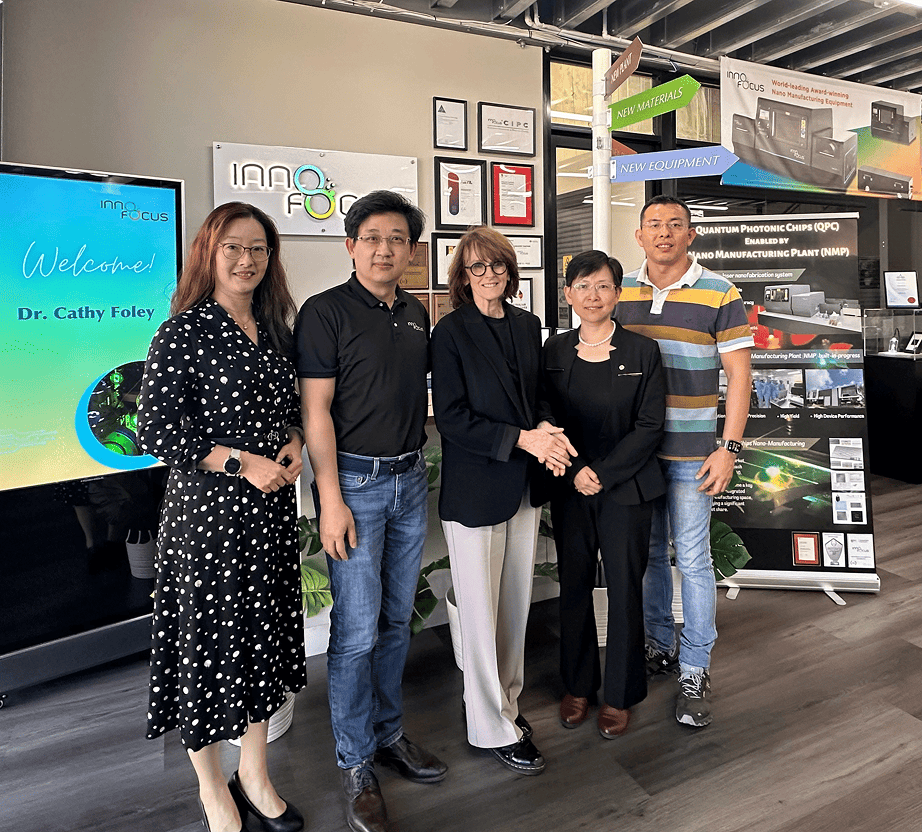

Welcome Dr Cathy Foley Joining Innofocus’s QPC discussion

Locations

Melbourne, Australia

Global HQ and Nano Manufacturing Plant (NMP)

Unit 10/17 Helen Street, Heidelberg West, VIC 3081, Australia

- [email protected]

- +61 3 9077 8119

Melbourne, Australia

Customer Innovation and Practice Center (CIPC)

Unit 9/17 Helen Street, Heidelberg West, VIC 3081, Australia

- [email protected]

- +61 3 9077 8119

Resources For You

Access to our product manuals, product catalogs, webinars, online laser training course and other resources via your Innofocus account.

Subscribe our newsletter