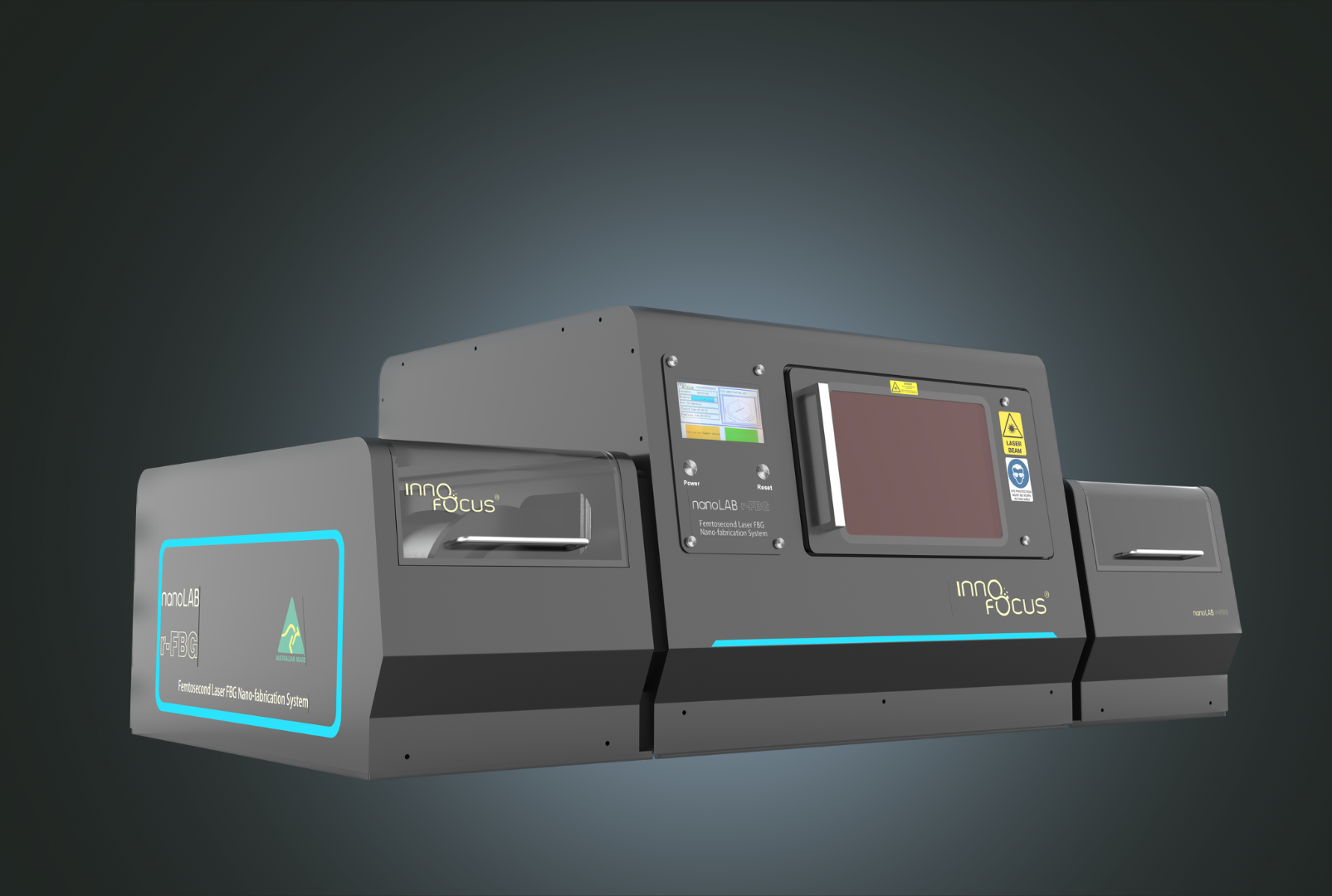

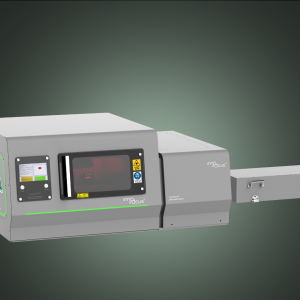

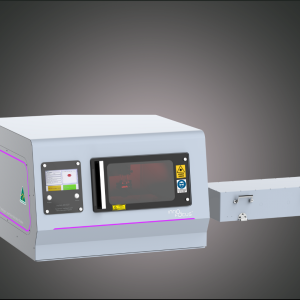

nanoLAB Roll-to-Roll FBG Fabrication (r-FBG)

The world-first commercialized manufacture equipment integrated with rollers specialized for fiber delivery and fiber collection.

nanoLAB Roll-to-roll FBG Fabrication System (r-FBG) has the following product features:

- Continuously fabricate FBG arrays up to kilometer length

- Intelligent fiber core recognition for automated FBG fabrication process to achieve high speed, high quality and high yield

- Position-Time Synchronization Trigger function to guarantee uniform periodic grating structure

- In-situ real-time measurement of FBG transmission and reflection when combining with a spectrometer

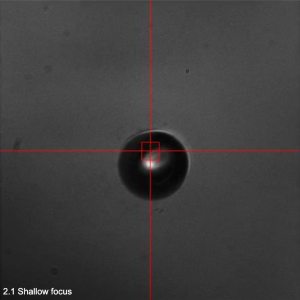

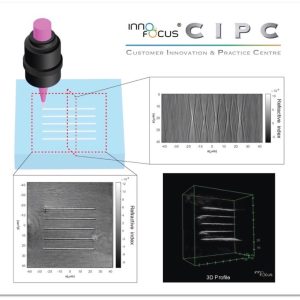

- Customized in-situ 3D refractive index characterization system for measuring 3D refractive index spatial distribution with a high accuracy of 0.0001

- Customized fixtures with accurate strain monitoring ranging from 0-30N with a high accuracy of 0.03N

- Build-in recipes for directly fabricating different FBGs with various specification

- Capability of fabricating high reflectivity (R>90%) and weak (R<1%) FBGs, as well as FBG strings with different central wavelengths and reflectivity

High Resolution

High Efficiency

High Accuracy

High Device Performance

High Yield

Industry Challenge

Fibre Bragg gratings (FBGs) manufactured by femtosecond laser technology possess significant advantages over conventional FBGs fabricated by ultraviolet lasers. This is due to the large refractive index difference introduced by a femtosecond laser, which can be up to 10-3 (Δn ∽ 10-3). FBGs manufactured by femtosecond laser pulses offer three major advantages:

- Achieving a high reflectivity with a short grating length.

- Femtosecond laser manufactured FBGs can work in a high-temperature environment.

- Capability and high flexibility of processing different types of FBGs, e.g. FBGs with ultra-narrow bandwidth, ultra-wide bandwidth, apodized FBGs, chirped FBGs etc.

However, currently the cost of femtosecond-laser processed FBG products is significantly greater than that of traditional UV laser processed FBG products. Meanwhile, the performance parameters of current femtosecond FBG products cannot be well-controlled with precision and stability. The yield rate is also low. Such issues limit the broad applications of femtosecond FBG.

To elaborate, the problems arise from the following three challenges of femtosecond laser FBG processing :

Conventional method of processing FBG using femtosecond laser is incapable of achieving precise quantitative product standardization (eg. reflectivity, central wavelength, bandwidth, etc)

During femtosecond laser processing, the accurate control of the femtosecond laser power stability as well as the precise synchronization of exposure time and speed of the displacement stage, are the rigorous requirements for precise processing of FBG with fine quantitative measures of identical performance index.

Difficulty of quantitatively fabricating FBG strings with identical performance indexes in large scale on a single long-distance fiber

In industrial application scenarios, it is required to process multiple FBGs continuously on fibre of kilometer-length for applications under extreme conditions, to achieve simultaneously multi-point measurements over long distance. This poses a challenge to mass-produce FBG strings with standardized performance specs in large scale on a single long fiber.

Low degree of automation hinders the development of high-yield large-scale FBG fabrication

The current femtosecond laser fabrication approach relies heavily on human manual control based on the expertise of the operator. Low degree of automation in the approach hence poses a challenge to achieve large-scale fabrication of FBGs with high quality, high device performance and high yield as well as repeatability.

Product Performance

PowerFlex Module: Precise control of laser power

High power stability and precise power control are essential to guarantee the high-quality manufacturing of fiber Bragg grating (FBG). PowerFlex is a fully automated laser power control technology that enables precise control of laser power at a step of 1µW.

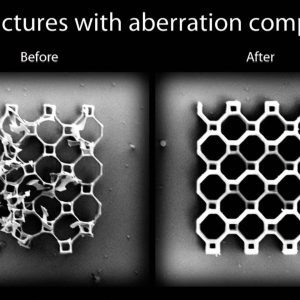

During the manufacturing process, the controlled exposure time can be very precise, at the order of 0.001ms, so the exposure time can be maintained very consistently. In addition, controlling laser power stability is essential to ensure consistent refractive index differences. In this regard, Innofocus uses a highly stable femtosecond laser with a real-time pulse power monitoring system. The monitoring system guarantees the stability of laser pulses during long-time continuous operation (>100 hours), and the fluctuation of a single pulse can be controlled within <1%. It enables continuous stable FBG manufacturing and ensures the consistency of the refractive index of each point. It lays a solid foundation for realizing high-performance FBG manufacturing. A schematic of the comparison is shown in Figure 1. Suppose the laser power is not stable. In that case, the distribution of refractive index within the fiber during manufacturing will be uneven, as shown in the case of Figure A, causing an overall lower quality of FBG. Innofocus’s high-stability laser can output stable power values for a long time to ensure a uniform refractive index distribution.

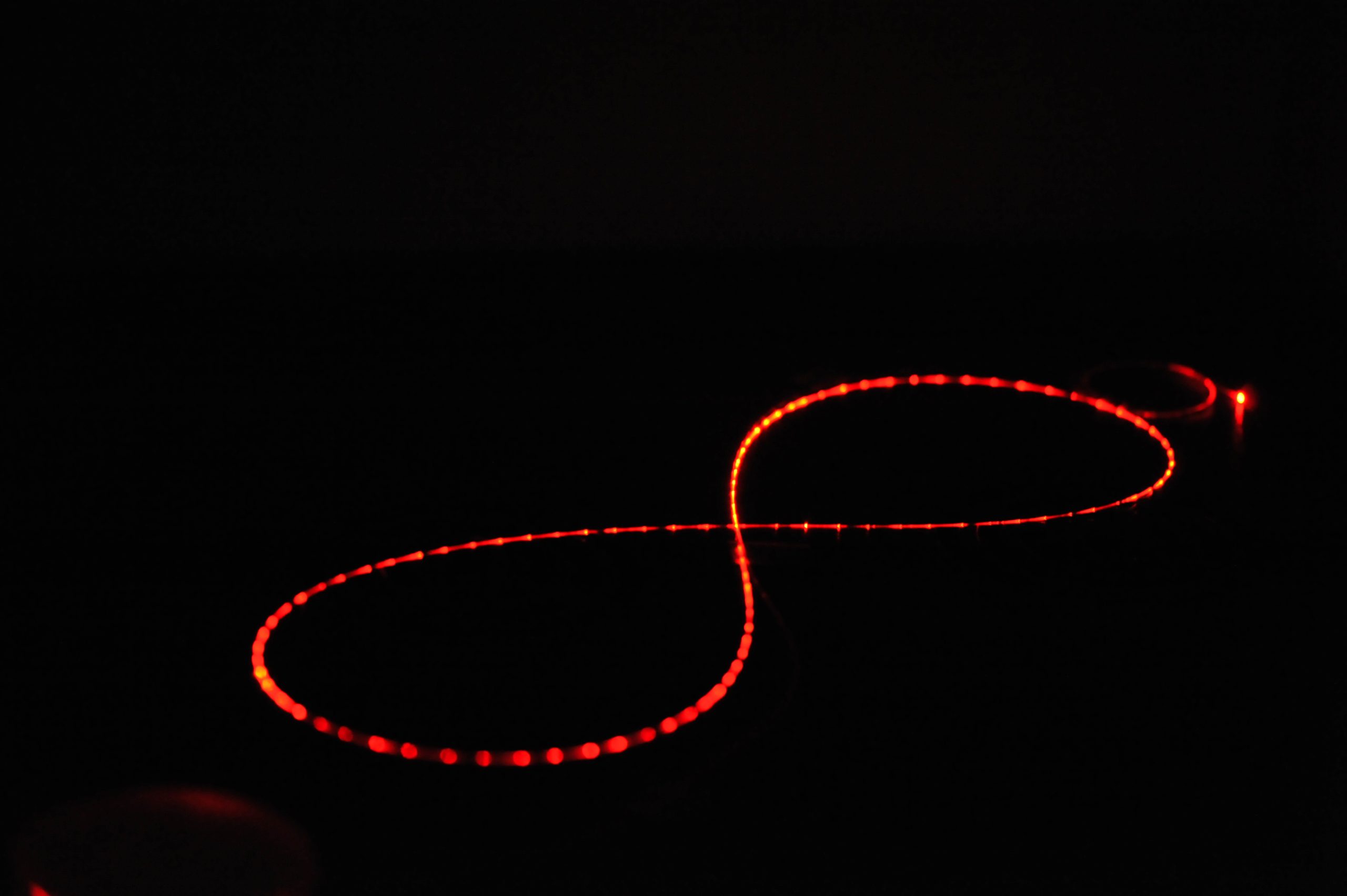

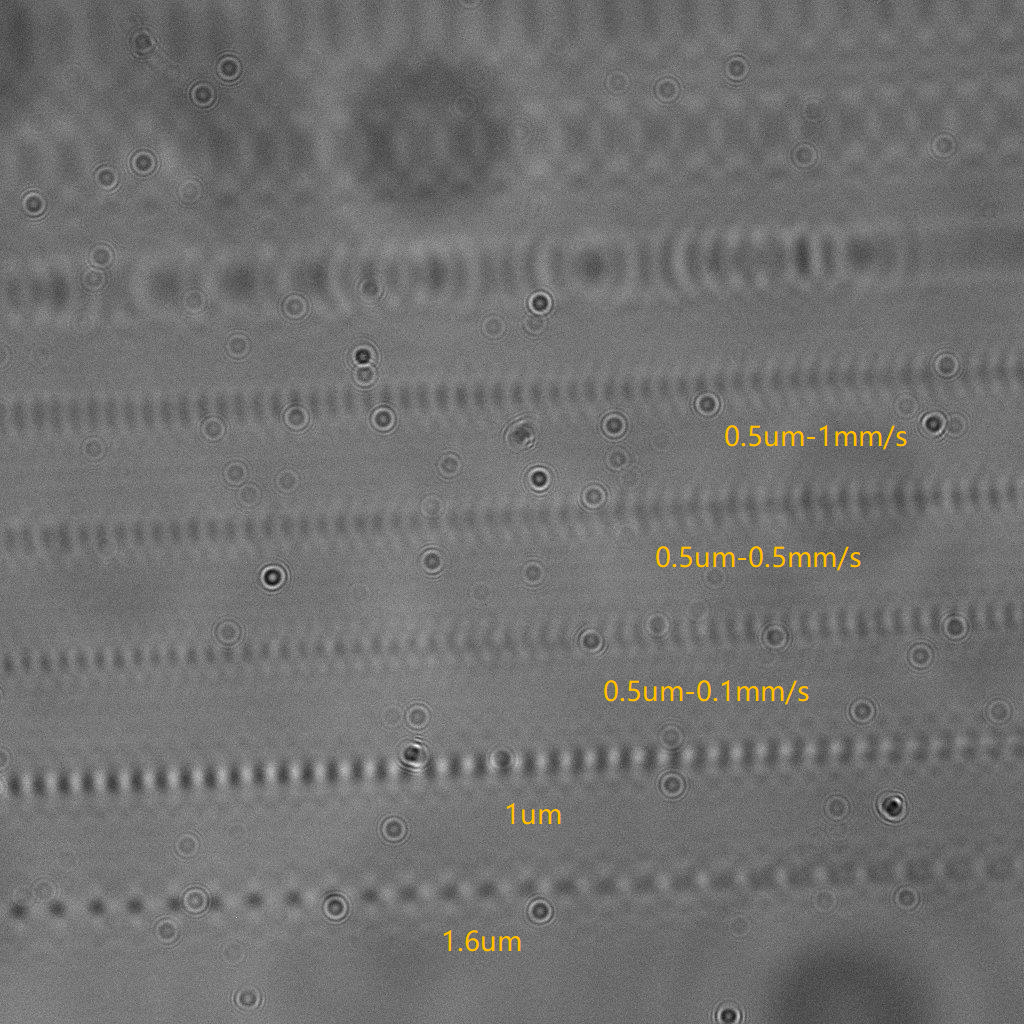

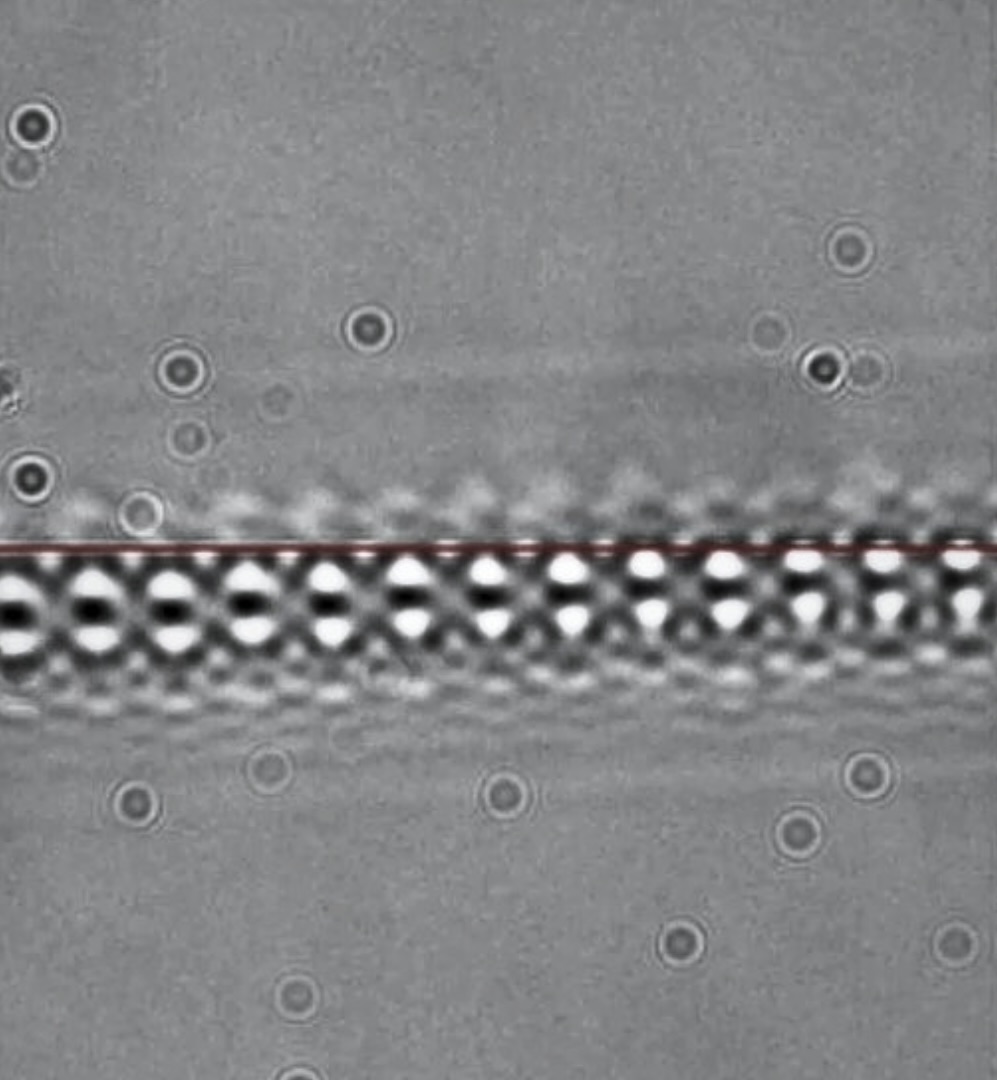

Fig 1. Comparison of FBG grid points for stable and unstable laser power processing. The blue line represents the fiber core and the dot represents the grid point of laser processing

Flexibility in various laser power control

Our intelligent femtosecond laser power control technology can also meet the needs of introducing different refractive index distributions. As shown in Figure 2, the points in an FBG manufactured by a high laser power are larger in size with a higher refractive index change (Figure A), whereas points manufactured at a low power are smaller in size (Figure B). By changing the system’s parameters, various flexible needs can be met. The fully automated power system effectively avoids the variation in quality caused by laser power fluctuation. It allows for long-time, large-scale, repeated FBG manufacturing, resulting in high-quality mass production of FBG.

Fig 2. Schematic figure of FBG points processed with different laser processing powers.

High power stability

Position-Time Synchronization Trigger function

Roll-to-roll fiber delivery and fiber collection

Applications